Document Type

Emerging StandardPublished date

03/15/2024Input Close Date

To be determinedScientific Experts

Dom Vicchio (Sr. Director, USP)

Introduction

To jump-start the consideration of the potential standards development process and have earlier stakeholder engagement, USP is piloting a new approach for developing and sharing information with our stakeholders. Through a collaboration between USP’s Small Molecules Department and the Global Analytical Development Laboratory, methods will be developed and validated for drug substances and drug products for which no monographs are currently available. The Emerging standards are intended to improve USP’s official standards elaboration process by increasing transparency and allowing for broader stakeholder participation by publishing on the USP website prior to formal notice and comment through publication in the Pharmacopeial Forum.

Clindamycin Phosphate Injection has been evaluated and shown to be a suitable candidate for development under this new program. The methods, in this document, are being published to help analyze Clindamycin Phosphate Injection as a part of USP’s mission to improve global health through public standards that help ensure the safety, quality, and benefit of medicines and foods.

Certain commercial equipment, instruments or materials may be identified in this document to specify adequately the experimental procedure. Such identification does not imply approval, endorsement, or certification by USP of a particular brand or product, nor does it imply that the equipment, instrument, or material is necessarily the best available for the purpose or that any other brand or product was judged to be unsatisfactory or inadequate.

This document is not a USP compendial standard and is intended to serve as a resource for information purposes only. It does not reflect USP or USP’s Expert Body opinions of future revisions to the official text of the USP-NF. Parties relying on the information in this document bear independent responsibility for awareness of, and compliance with, any applicable federal, state, or local laws and requirements.

Background

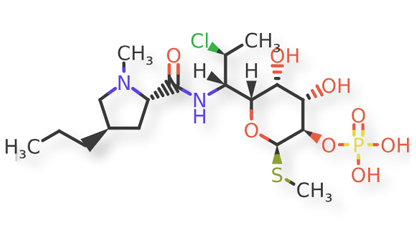

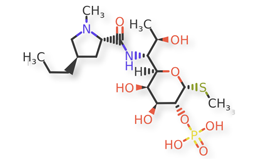

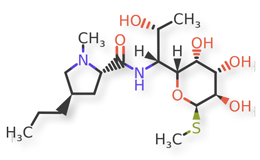

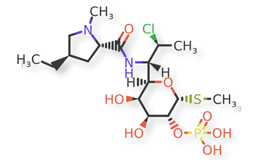

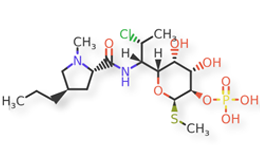

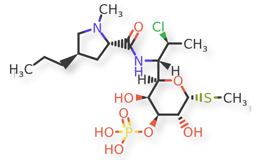

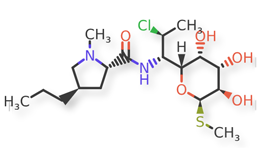

Clindamycin Phosphate (Methyl 7-chloro-6,7,8-trideoxy-6-(1-methyl-trans-4-propyl-L-2- Pyrrolidine carboxamido)-1-thio-L-threo-α-D-galacto-octopyranoside 2-(dihydrogen phosphate)) classified as a lincosamide antibiotics. It exhibits primarily bacteriostatic action against gram-positive aerobes and a broad spectrum of anaerobic bacteria. The action of clindamycin is predominantly bacteriostatic although high concentrations may be slowly bactericidal against sensitive strains. Although clindamycin phosphate is inactive in vitro, rapid in vivo hydrolysis converts this compound to active antibacterial form of clindamycin1.

No pharmacopeia currently provides a monograph for Clindamycin Phosphate Injection. Upon evaluating the USP Clindamycin Phosphate drug substance monograph, the Clindamycin Phosphate Gel PF procedure2, and the Clindamycin Phosphate EP monograph3 for the suitability of Clindamycin Phosphate injection, it was observed that one of the major peroxide degradation products was getting merged with Benzyl alcohol, an excipient present in the Clindamycin Phosphate injection in all the referenced procedures.

Ultimately, an OI procedure has been developed for Clindamycin Phosphate Injection. This finalized method utilizes an Eclipse XDB C8 (250 X 4.6) mm, 5 μm, packing (L7), at a column temperature of 40°C and a flow rate of 1.0 mL/min. The procedure employs gradient flow, with peaks detected at 205 nm, and has a total runtime of 75 min.

While this OI procedure can be adopted for the assay, it does require the full 75 min to complete. Consequently, attempts were made to develop a separate isocratic procedure with a shorter runtime. Unfortunately, these trials were unsuccessful due to the presence of adjacent peaks. Specifically, an unknown peak with a relative retention time (RRT) of 1.03 elutes immediately after the Clindamycin phosphate (main component), and Clindamycin 3-Phosphate with an RRT of 0.96 elutes just before the main component.

Considering the above findings, it has been determined that a gradient program is necessary for assay procedure. As a result, the gradient program described in the assay/OI procedure of the USP Clindamycin Phosphate Drug Substance (DS) monograph has been adopted. This particular gradient program with 46 min of runtime allows for effective separation of the main component as well as the adjacent peaks.

This document outlines methodologies and includes corresponding data obtained from chromatographic systems, aiming to achieve peak retention time correspondence and photodiode array (PDA) spectral conformity. These measures facilitate the identification of Clindamycin Phosphate in the presence of different impurities and excipients. Furthermore, the document encompasses High-Performance Liquid Chromatography (HPLC) techniques and validation data, which are well-suited for precise determination of the strength and purity of Clindamycin Phosphate in Clindamycin Phosphate injection.

Clindamycin Phosphate and related impurities are shown in Figures 1 and 2.

EXPERIMENTAL

Materials:

Clindamycin Phosphate and its associated impurities, such as Clindamycin Hydrochloride and Lincomycin Hydrochloride, can be found in the USP catalogue4. Additionally, Clindamycin 3-phosphate, available as a bulk material, is sourced from the USP. Lincomycin 2-phosphate, Clindamycin B Phosphate, and 7-Epi clindamycin phosphate are obtained from Hemarsh Technologies5.

The evaluation of identification, including ultraviolet (UV) spectral match and retention time match, as well as the assay and impurity analyses described in this document, were performed using a commercial Clindamycin injection sample.

IDENTIFICATION

The determination of clindamycin phosphate in Clindamycin Phosphate Injection was carried out through the utilization of HPLC-UV with a photodiode array (PDA) detector. Additionally, the chromatographic HPLC retention time was compared for the identification of Clindamycin Phosphate.

A. HPLC-UV with PDA Detector:

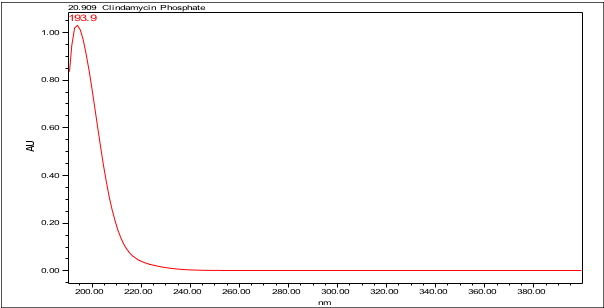

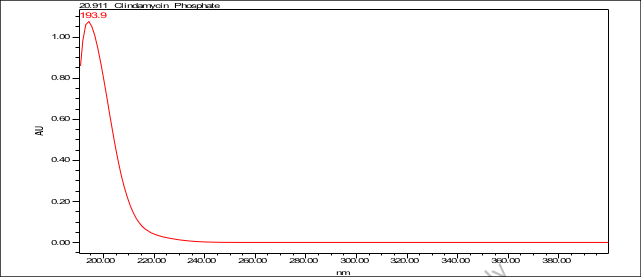

The HPLC assay procedure, incorporating a PDA detector, served as the chromatographic identification method. For specific details on the method conditions and solution preparations, please refer to the Assay section. The validation parameters and results are presented in Table 1, while Figures 3 and 4 display the UV spectra of the clindamycin phosphate standard and sample for comparison.

| Parameter | Samples and Procedures | Results |

| Spectral Agreement | Collect PDA data from 190–400 nm for the Standard solution and Sample solution | The UV spectrum of the Clindamycin Phosphate peak from the Sample solution matched the spectrum of clindamycin phosphate in the Standard solution and exhibited maxima at the same wavelengths as the Standard solution |

| Abbreviation: PDA, Photodiode array; UV, ultraviolet | ||

Figure 4. UV spectrum of clindamycin phosphate from the Sample solution

B. Retention Time Match:

An orthogonal test utilized for the identification of Clindamycin Phosphate involves the use of chromatographic retention time. The HPLC assay procedure was employed for this identification test. For specific information regarding the method conditions and solution preparations, please refer to the Assay section.

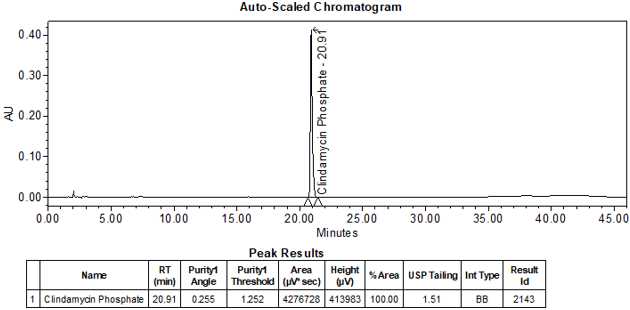

The validation parameter and corresponding results are summarized in Table 2, Additionally, Figures 5 and

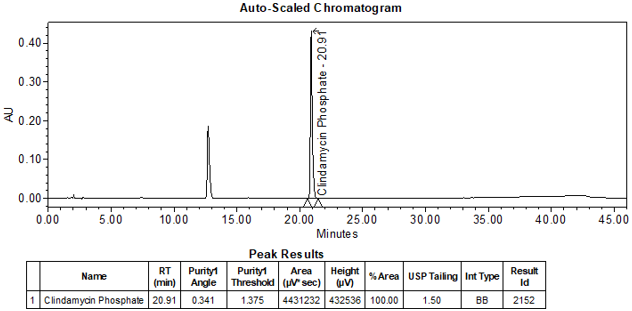

6 depict the example chromatograms for the Standard solution and Sample solution, respectively.

| Parameter | Samples | Results |

| Retention Time Match | Standard solution and Sample solution | The relative standard deviation (%RSD) of the Clindamycin Phosphate peak retention time for all injections (n=19) of the Standard solution and Sample solution was <1.0. |

Figure 5. Chromatogram of Standard solution using HPLC assay procedure

Figure 6. Chromatogram of Sample solution using HPLC assay procedure

Note: Please note that the peak observed at approximately 12.7 min corresponds to Benzyl alcohol, which is an excipient present in Clindamycin phosphate injection.

ASSAY

A gradient reversed-phase HPLC method was developed to analyze the assay in Clindamycin Phosphate Injection. This procedure was validated according to the guidelines outlined in USP General Chapter <1225>, Validation of Compendial Procedures6. It was determined to be specific, linear, accurate, precise, robust, and without any interference for the evaluated samples.

Chemicals:

Ortho-phosphoric acid 88% (EMPARTA grade), Ammonia solution 28-30% (EMPARTA grade), Methanol (HPLC grade), and Acetonitrile (HPLC grade) were procured from Merck. Acetonitrile (LC-MS grade) was obtained from J.T. Baker. Ultrapure water used for HPLC analysis was acquired from a Sartorius water purification system.

Instruments and method:

The analysis of Clindamycin Phosphate Injection was performed using Waters Alliance e 2695 and Agilent infinity 1260 series with PDA detector, and the results were processed by Empower (Waters software). The Zorbax Eclipse XDB C8, 80Å, (250 × 4.6) mm, 5 µm, from Agilent was used for analysis. The analysis was performed at 40°C of column temperature, with a flow rate of 1.2 mL/min and 20 µL as the injection volume. Autosampler temperature was kept at 10°C. The PDA detector was set at 190-400 nm wavelength and the detection of clindamycin phosphate was at 205 nm. All the solutions are protected from light and prepared in low actinic glassware. Analyzed with a gradient program as listed in Table 3.

| Time (min) | Solution C (%) | Solution D (%) |

|---|---|---|

| 0 | 95 | 5 |

| 40 | 5 | 95 |

| 41 | 95 | 5 |

| 46 | 95 | 5 |

Solutions:

Solution-A: Add 14 mL of phosphoric acid into 4000 mL of water. Add 10 mL of ammonia solution and adjust the pH to 5.5 with ammonia solution

Solution-B: Mix Acetonitrile: Methanol (900:100, v/v)

Solution-C: Solution B: Solution A (80:920, v/v)

Solution-D: Solution B: Solution A (480:520, v/v)

Diluent: Solution B: Solution A (20:80, v/v)

Preparation of System suitability solution: 0.5 mg/mL of USP Clindamycin Phosphate RS and 0.0025 mg/mL of Clindamycin 3-phosphate in Diluent

Preparation of Standard solution: 0.5 mg/mL of Clindamycin from USP Clindamycin Phosphate RS in Diluent.

Preparation of Sample solution: 0.5 mg/mL of Clindamycin from Clindamycin Phosphate injection was prepared as follows.

Sample stock solution (5 mg/mL of Clindamycin): Transfer accurately 167 µL of Clindamycin Phosphate injection solution (equivalent to 25.0 mg of Clindamycin) into 5-mL volumetric flask, dilute with Diluent to volume and mix well.

Sample solution (0.5 mg/mL of Clindamycin): Transfer accurately 1.0 mL of Sample stock solution into 10- mL of volumetric flask, dilute with Diluent to volume and mix well.

Analytical parameters and validation:

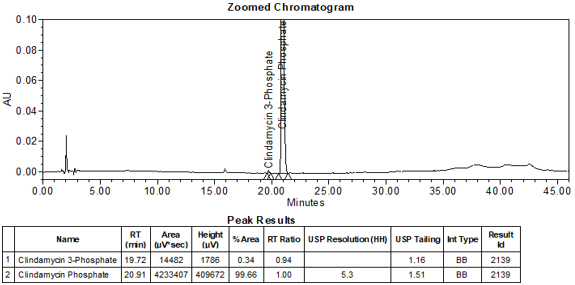

The chromatographic conditions underwent robustness checks and validation to assess specificity, linearity, precision, and accuracy as described in USP general chapter <1225>6. The system suitability requirements are summarized in Table 4. The validation parameters, solutions, and results for Clindamycin Phosphate Injection are summarized in Table 5. The example chromatograms for the assay system suitability solution, Standard and Sample solution are shown in Figures 7, 5 and 6, respectively.

| Parameter | Solution | Results |

|---|---|---|

USP Resolution (HH) Between Clindamycin 3-Phosphate and Clindamycin Phosphate | System suitability solution |

5.3 (See Figure 7) |

Retention Time (min) Clindamycin 3-Phosphate Clindamycin Phosphate | System suitability solution |

19.72 20.91 (See Figure 7) |

Relative Retention Time (s) Clindamycin 3-Phosphate Clindamycin Phosphate | System suitability solution |

0.94 1.00 (See Figure 7) |

| USP Tailing | Standard solution | Tailing was NMT 2.0 |

| System Precision (for 5 replicate injections) | Standard solution | %RSD was NMT 0.5 |

| Abbreviation: RSD, relative standard deviation; NMT, not more than | ||

| Parameter | Solutions | Results |

|---|---|---|

| Specificity (Chromatographic Separation) Peak Purity Analysis (Spectral Homogeneity) | Blank (Diluent), System suitability solution, Standard solution, and Sample solution | Any impurity peak from the Standard solution and Sample solution of drug product was separated from the Clindamycin Phosphate peak by a resolution ≥2.0 The PDA data from 190–400 nm showed homogeneity of UV spectrum for the Clindamycin Phosphate peak, indicating the lack of coelution. |

| Linearity | Linearity solutions from 50% to 150% of the nominal sample concentration (0.25, 0.375, 0.50, 0.625, and 0.75 mg/mL of Clindamycin Phosphate) | The correlation coefficient (r) was not less than 0.999 The bias of the linearity curve due to the intercept not being zero was less than ± 2.0% |

| Accuracy | Prepare Sample solutions spiked with three levels of the Standard solution, at 10%, 20%, and 30% of the nominal sample concentration in triplicate. 110% (0.55mg/mL), n=3 120% (0.60mg/mL), n=3 130% (0.65mg/mL), n=3 | The average recovery at each level was within 100 ± 3.0% |

| Repeatability | Repeatability solutions: 6 Sample solutions | The %RSD of the assay results was NMT 2.0 (n=6) |

| Intermediate Precision | Intermediate precision was done by a different analyst, on a different day by using a different make of instrument and different serial number of the column. | The %RSD of the assay results was NMT 2.0 (n=6) The %RSD was NMT 3.0 for the combined data of the first and second analysts (n =12) |

| Solution Stability | Standard solution and Sample solution | Standard solution and Sample solution were stable for 40 h at a sample cooler temperature of 10°C. |

| Sample Assay Test | Sample solution | 100.1 % for the source of the drug product tested. |

ORGANIC IMPURITIES

The HPLC method used to analyze organic impurities in Clindamycin Phosphate Injection is the same as the procedure described in the Assay section except gradient programme and flow rate. This method can effectively measure degradation products in the Clindamycin Phosphate Injection. By following the validation criteria outlined in <1225>6, the procedure was found to be specific, accurate, precise, robust, linear, and free from interference when applied to the tested samples. The validation study verified that this method is suitable for evaluating organic impurities in the Clindamycin Phosphate injection.

Instruments and method for OI:

The analysis of Clindamycin Phosphate Injection was performed using Waters Alliance e 2695 and Agilent infinity 1260 series with PDA detector, and the results were processed by Empower (Waters software). The Zorbax Eclipse XDB C8, 80Å, (250 × 4.6) mm, 5 µm, from Agilent was used for analysis. The analysis was performed at column temperature of 40°C, with a flow rate of 1.0 mL/min and 20 µL as the injection volume. Autosampler temperature was kept at 10°C. The PDA detector was set at 190-400 nm wavelength and the

detection of chromatogram was at 205 nm. All the solutions are protected from light and prepared in low actinic glassware. Analyzed with a gradient program as listed in Table 6.

| Time (min) | Solution C (%) | Solution D (%) |

|---|---|---|

| 0 | 90 | 10 |

| 10 | 90 | 10 |

| 35 | 58 | 42 |

| 55 | 25 | 75 |

| 60 | 25 | 75 |

| 63 | 90 | 10 |

| 75 | 90 | 10 |

Solutions for OI:

Prepare Solutions for Mobile phase, Diluent as per the assay procedure.

Note:

- Clindamycin phosphate serves as the prodrug for Clindamycin, and the drug product's label indicates that "Each mL contains Clindamycin Phosphate USP equivalent to 150 mg of Clindamycin." The concentrations of the standard solution and sample solution are specified in terms of Clindamycin.

- To address the presence of approximately 2.2% Clindamycin 3-phosphate and 2.3% Clindamycin phosphate in the 7-Epiclindamycin phosphate impurity, separate linearity and accuracy studies are scheduled for 7-Epiclindamycin phosphate. This approach aims to prevent or eliminate any potential interference in the areas corresponding to Clindamycin 3-phosphate and Clindamycin phosphate.

- The validation process will encompass a range of 0.05% to 5.0% for all impurities, excluding Clindamycin. However, for Clindamycin, the validation range will extend from 0.05% to 10%, with respect to 5 mg/mL Clindamycin from Clindamycin phosphate injection.

Preparation of Impurity mixture stock solution 1:

Impurity mixture stock solution 1 consisting of 1.0 mg/mL each of Lincomycin Phosphate, Lincomycin, Clindamycin B 2-Phosphate, Clindamycin 3-phosphate was prepared by dissolving the appropriate amounts of each impurity in Diluent with the aid of sonication.

Preparation of 7-Epiclindamycin phosphate stock solution 1:

7-Epiclindamycin phosphate stock solution 1 consisting of 1.0 mg/mL of 7-Epiclindamycin phosphate was prepared by dissolving an appropriate amount of 7-Epiclindamycin phosphate in Diluent with the aid of sonication.

Preparation of Clindamycin stock solution 1:

Clindamycin stock solution 1 consisting of 2.0 mg/mL of Clindamycin was prepared by dissolving an appropriate amount of Clindamycin Hydrochloride in Diluent with the aid of sonication.

Preparation of USP Clindamycin phosphate RS stock solution 1:

USP Clindamycin phosphate RS stock solution 1 (1.0 mg/mL of Clindamycin from USP Clindamycin phosphate RS) was prepared by dissolving an appropriate amount of USP Clindamycin Phosphate RS in Diluent.

Preparation of Impurity mixture stock solution 2:

Impurity mixture stock solution 2, containing 0.05 mg/mL of all impurities except 7-Epiclindamycin phosphate, was prepared from the Impurity mixture stock solution 1 and Clindamycin stock solution 1 by further diluting with the Diluent.

Preparation of 7-Epiclindamycin phosphate stock solution 2:

7-Epiclindamycin phosphate stock solution 2, containing 0.05 mg/mL of 7-Epiclindamycin phosphate, was prepared from the 7-Epiclindamycin phosphate stock solution 1 by further diluting with the Diluent.

Preparation of USP Clindamycin phosphate RS stock solution 2:

USP Clindamycin phosphate RS stock solution 2, containing 0.05 mg/mL of Clindamycin, was prepared from the USP Clindamycin phosphate RS Standard stock solution 1 by further diluting with the Diluent.

Preparation of System suitability solution:

A solution consisting of 5.0 mg/mL of USP Clindamycin Phosphate RS and 0.05 mg/mL (or) 1% of all impurities was prepared by combining appropriate amount of USP Clindamycin Phosphate RS with appropriate volume of each Clindamycin stock solution 1, Impurity mixture stock solution 1 and 7-Epiclindamycin phosphate stock solution 1 in Diluent.

Preparation of Sensitivity solution:

A solution consisting of 2.5 μg/mL (0.05% of the sample concentration) each of Lincomycin 2-phosphate, Lincomycin, Clindamycin B phosphate, 7-Epiclindamycin phosphate, Clindamycin 3-phosphate, Clindamycin phosphate and Clindamycin was prepared by combining appropriate volume of Impurity mixture stock solution 2, 7-Epiclindamycin phosphate stock solution 2 and USP Clindamycin phosphate RS stock solution 2 in Diluent.

Preparation of Standard solution 1:

A solution consisting of 5 μg/mL of Lincomycin 2-phosphate, Lincomycin, Clindamycin B phosphate, Clindamycin 3-phosphate, Clindamycin phosphate and Clindamycin was prepared by combining appropriate volume of Impurity mixture stock solution 2 and USP Clindamycin phosphate RS stock solution 2 in Diluent.

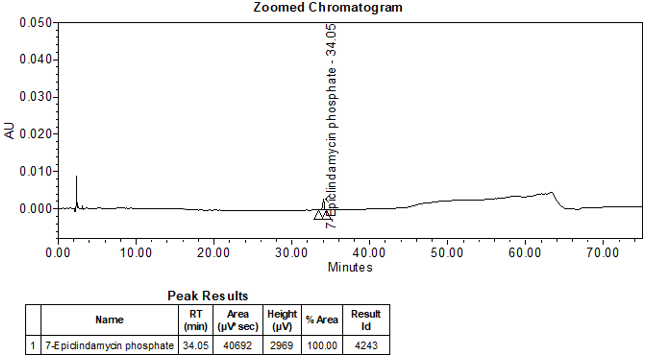

Preparation of Standard solution 2:

A solution consisting of 5 μg/mL of 7-Epiclindamycin phosphate was prepared from 7-Epiclindamycin phosphate stock solution 2 in Diluent.

Preparation of Sample solution:

Nominally 5 mg/mL of clindamycin from Clindamycin Phosphate injection preparation is as follows.

Transfer accurately 67 μL of Clindamycin Phosphate injection solution into 2 mL of volumetric flask, add 1933 μL of Diluent, and shake well to mix.

Label claim: Each mL contains Clindamycin Phosphate USP equivalent to 150 mg of Clindamycin.

Analytical parameters and validation:

The robustness of the optimized chromatographic conditions obtained from the OI was examined and validated through the assessment of specificity, linearity, accuracy, repeatability, intermediate precision, and sample analysis, following the guidelines outlined in USP General Chapter <1225>6. Linearity was determined for Clindamycin Phosphate and its associated impurities, while accuracy and repeatability were established for Clindamycin Phosphate related impurities.

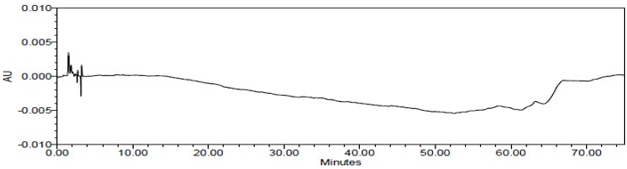

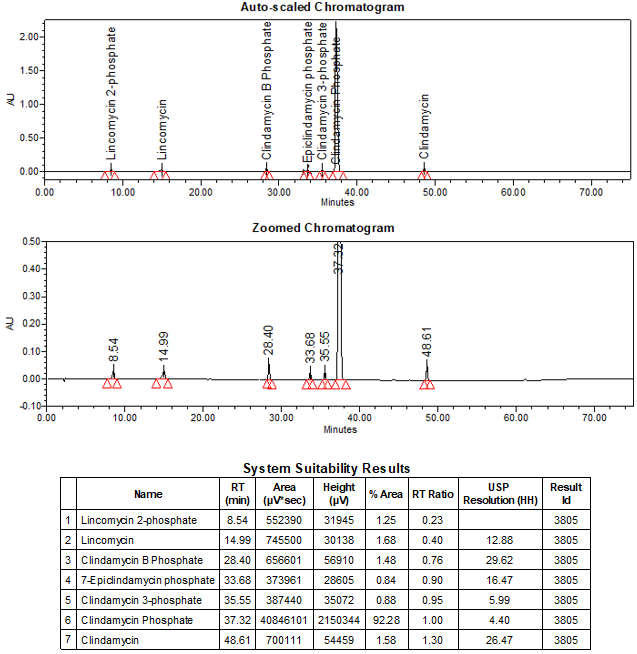

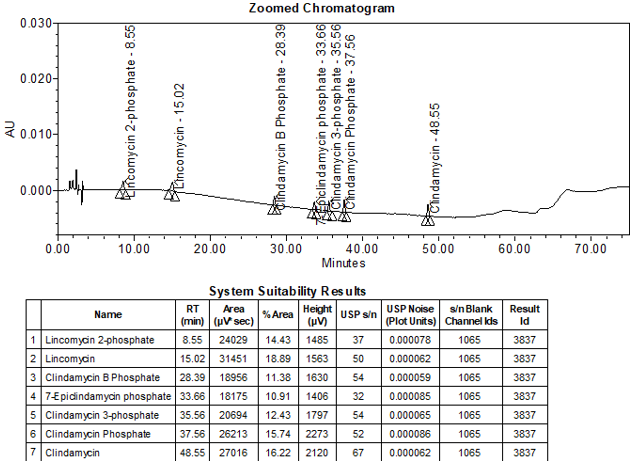

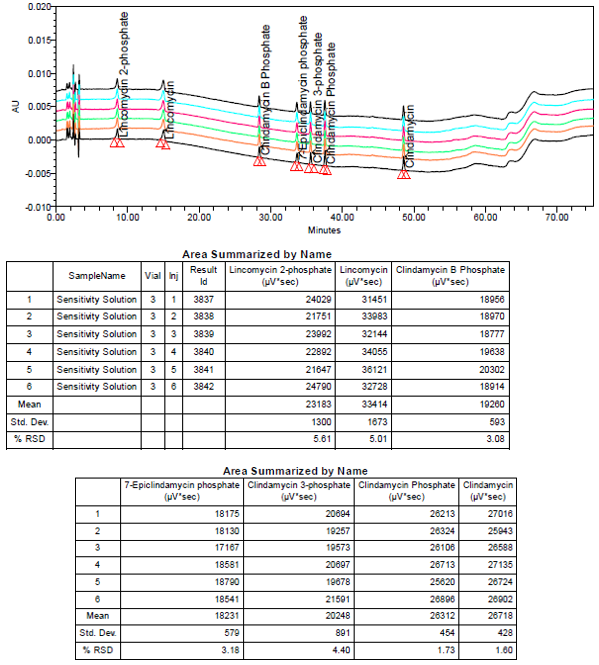

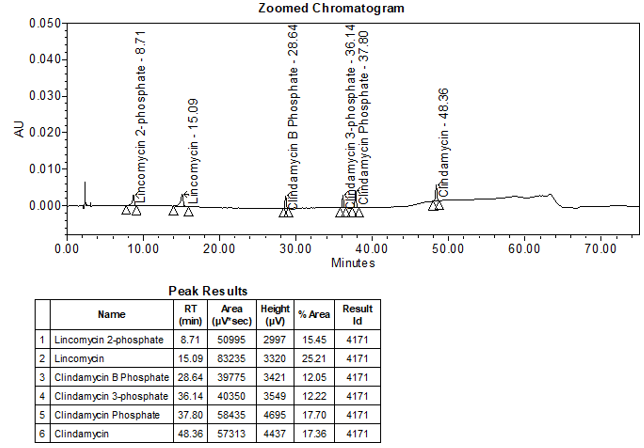

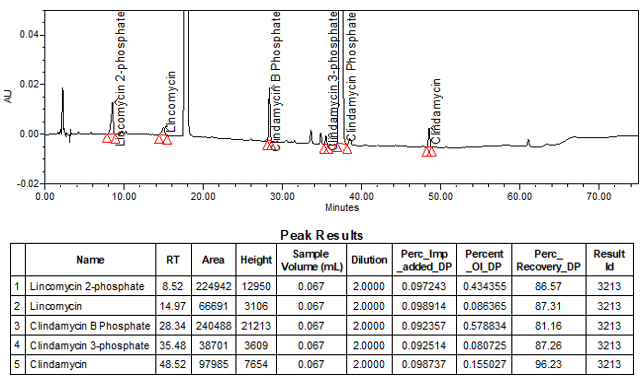

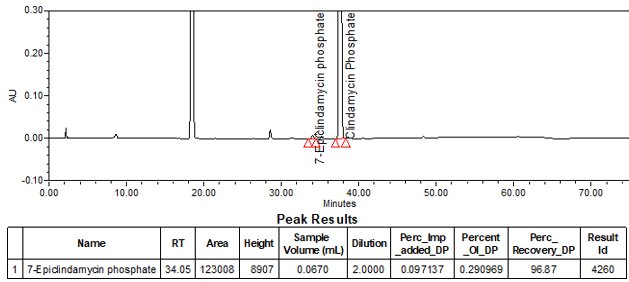

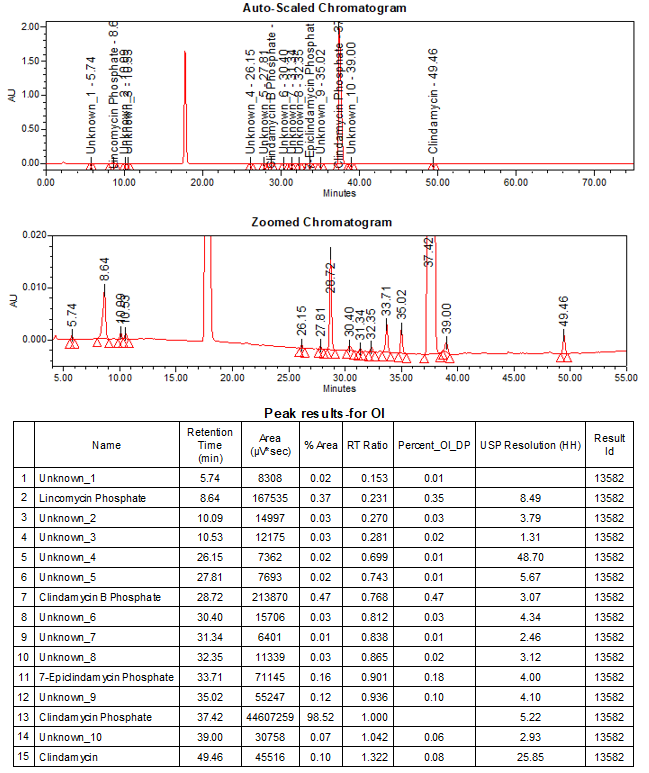

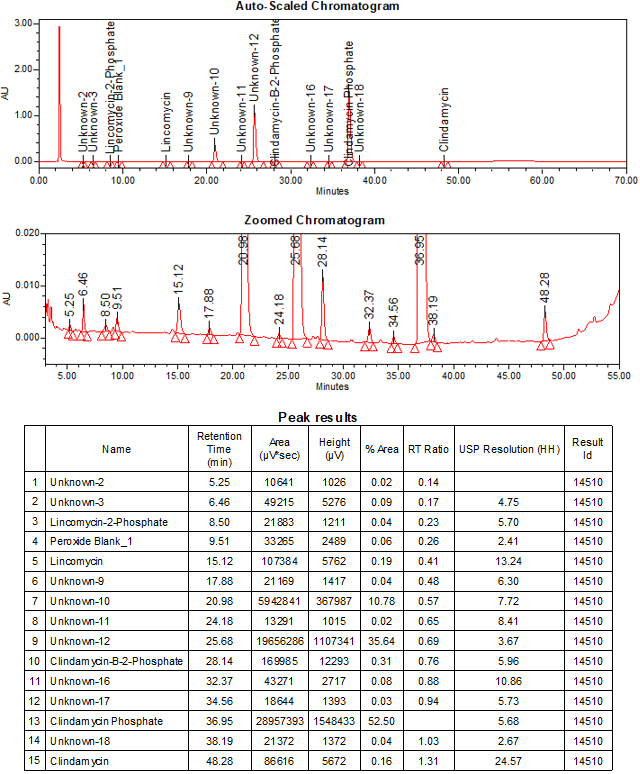

The limit of quantitation (LOQ) was established at 0.05% for all the components (API and impurities) of sample nominal concentration. The system suitability requirements are summarized in Table 7. The validation parameters and testing results for Clindamycin Phosphate Injection are summarized in Table 8. The example chromatograms of Blank (Diluent), System suitability solution, Sensitivity solution (0.05%), System precision for sensitivity solution(0.05%, n=6), Standard solution 1 (0.1%), Standard solution 2 (0.1%), sample solution spiked with known impurities at 0.10% and Sample solution are presented in Figures 8–16, respectively.

| Parameter | Solution | Results |

|---|---|---|

USP Resolution (HH) (Minimum resolution between any two components) Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin phosphate Clindamycin | System suitability solution |

NA 12.88 29.62 16.47 5.99 4.40 26.47 (See Figure 9) |

Retention Time (min) Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin phosphate Clindamycin | System suitability solution |

8.54 14.99 28.40 33.68 35.55 37.32 48.61 (See Figure 9) |

Relative Retention Time(s) Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin phosphate Clindamycin | System suitability solution |

0.23 0.40 0.76 0.90 0.95 1.00 1.30 (See Figure 9) |

System Precision Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin phosphate Clindamycin | Sensitivity solution |

5.01 3.08 3.18 4.40 1.73 1.60 (See Figure 11) |

USP Signal-to-Noise Ratio Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin phosphate Clindamycin | Sensitivity solution |

37 50 54 32 54 52 67 (See Figure 10) |

| Parameter | Solutions | Results |

|---|---|---|

| Specificity | Blank (Diluent), System suitability solution, Sensitivity solution, Sample solution and spiked sample solution at 0.10% | No interference between peaks of interest. Any impurity peak ≥0.05% total area was separated from the main peak by a resolution of ≥2.0, and from adjacent specified impurity peaks by a resolution of ≥1.5. |

Linearity Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin phosphate Clindamycin | Linearity solutions From LOQ (0.05%) to 5.0% of the nominal concentration of clindamycin and related impurities except Clindamycin in Diluent. For Clindamycin, Linearity from LOQ (0.05%) to 10.0% of the nominal concentration of clindamycin | The correlation coefficient of the linear curves for Clindamycin phosphate and the impurities were not less than 0.99 |

| Relative Response Factor (RRF) Values | Linearity solutions | For results, refer to Table 9. |

Accuracy Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin | Accuracy solutions: impurities except Clindamycin spiked in Sample solution at 3 levels: 0.10%: n=6 Accuracy solutions for Clindamycin: | The average recovery for each specified impurity except Clindamycin at each level were observed to be within: The average recovery for Clindamycin at each level were observed to be within: |

Repeatability Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin | Repeatability solutions: 6 spiked Sample solutions at the 0.10% level | The average recovery at 0.10% was within 100 ± The %RSD of the recovery See Figure 14 and 15 for example chromatograms. |

Intermediate Precision Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin |

Repeatability solutions: |

The average recovery at 0.10% was within 100 ±20.0% RSD of the 6 results at 0.10% was ≤ 10.0% RSD of the 12 results (for the 2 analysts) at 0.10% was ≤ 15.0% |

| Sample Analysis | Sample solution | See Figure 16. |

Solution Stability Lincomycin 2-phosphate Lincomycin Clindamycin B phosphate 7-Epiclindamycin phosphate Clindamycin 3-phosphate Clindamycin phosphate Clindamycin | Standard solution (0.10% ) and spiked Sample solution at 0.10% level. Freshly prepared samples analyzed (t=0). The samples were then stored at 10°C and analyzed periodically for up to 48 h. | Observed changes in the peak area from both solutions for each specified impurity and Clindamycin phosphate were within ± 10% of the initial time point values. 0.10% standard solution was found to be stable at 10° C for a period of 48 h and 0.10% Spiked sample solution was found to be stable at 10° C for a period of 48 h. |

| Robustness | Robustness solution 1 Robustness solution 2: (5 mg/mL of Clindamycin Phosphate, 0.005 mg/mL all impurities and peroxide extraction sample solution) Multifactorial robustness study conducted by using Design of Experiment (DOE) software was performed with change in flow rate (± 0.1 mL/min), column temperature (± 3°), mobile Phase pH ( ± 0.1), minor component in the gradient step hold (±2 %) and change in initial step of the gradient time. DOE studies were conducted using robustness solution 1, robustness solution 2. | System suitability criteria for resolution, tailing factor, and relative retention time met across all evaluated conditions. |

| S. No | Component name | RRF |

|---|---|---|

| 1 | Lincomycin 2-phosphate | 0.96 |

| 2 | Lincomycin | 1.43 |

| 3 | Clindamycin B Phosphate | 0.76 |

| 4 | Clindamycin 3-Phosphate | 0.76 |

| 5 | Clindamycin Phosphate | 1.00 |

| 6 | Clindamycin | 1.00 |

| 7 | 7-Epiclindamycin phosphate | 0.73 |

| RRF values of the impurities were calculated by dividing the slope of the linearity curve for each impurity by the slope of the linearity curve for main component. | ||

Forced Degradation Study

Forced degradation study performed on Clindamycin Phosphate drug substance, major degradants were found in the stressed samples subjected to humidity degradation and peroxide degradation. During peroxide degradation, it was observed that two primary degradation products were generated after exposing the sample to 3% H2O2 solution for 30 minutes at room temperature (with relative retention times of approximately 0.568 and 0.695) (See Figure 17). Under humidity degradation conditions, Clindamycin Phosphate underwent degradation and transformed into Clindamycin.

The chromatographic method successfully separated all known and unknown impurity peaks from each other, and no coelution was observed with the main peak, ensuring adequate separation of the impurities.

Comment On [Methods for the Analysis of Clindamycin Phosphate Injection]

Submitted on version: